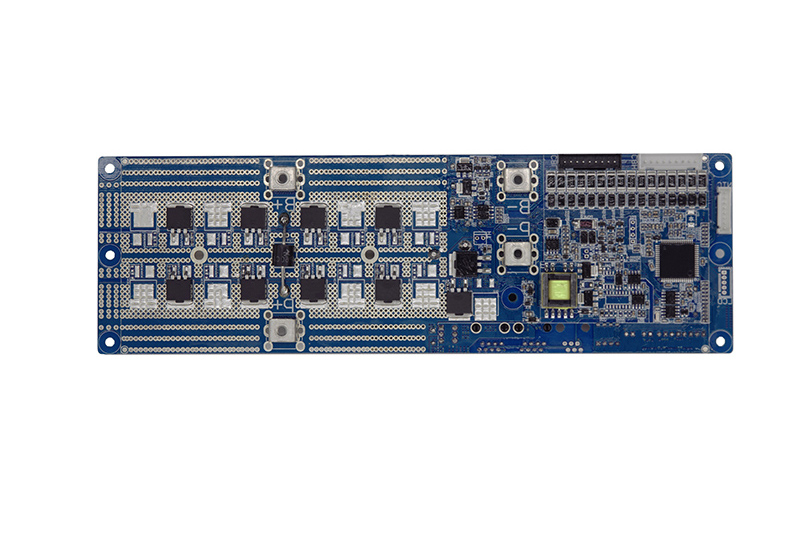

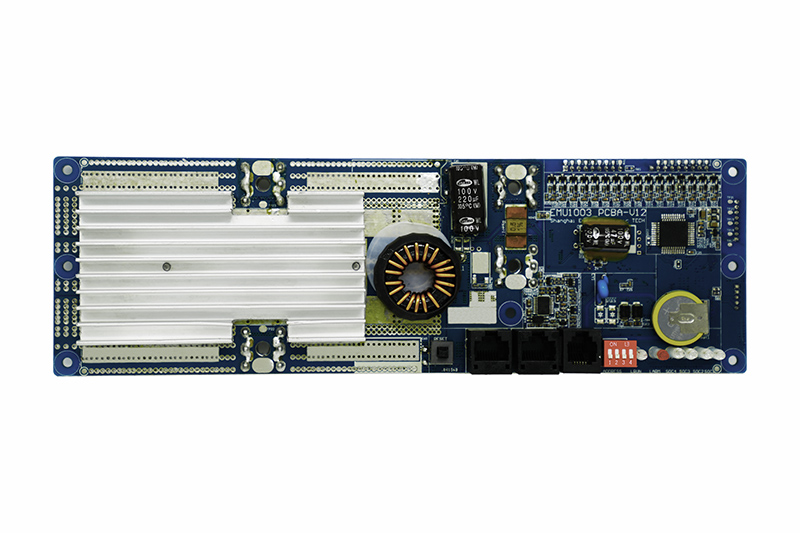

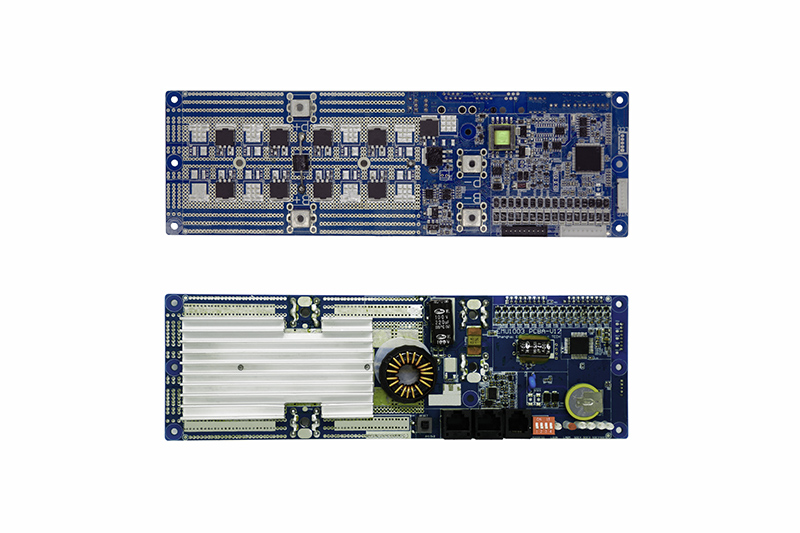

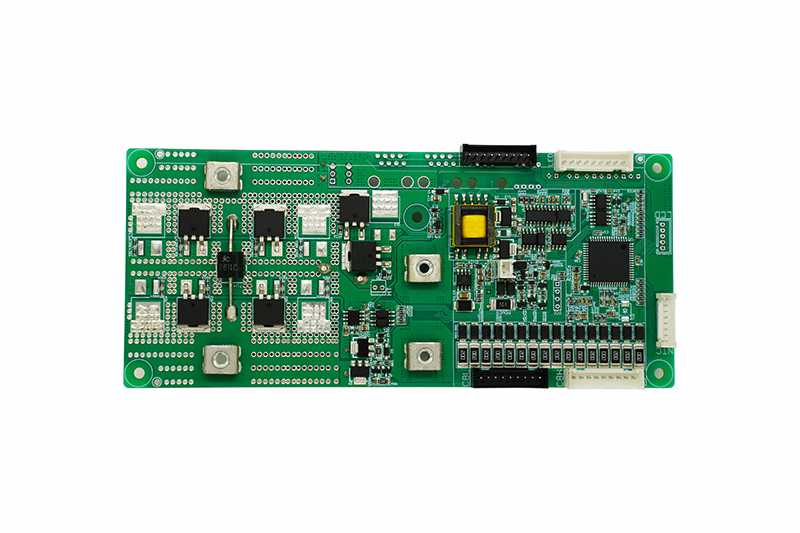

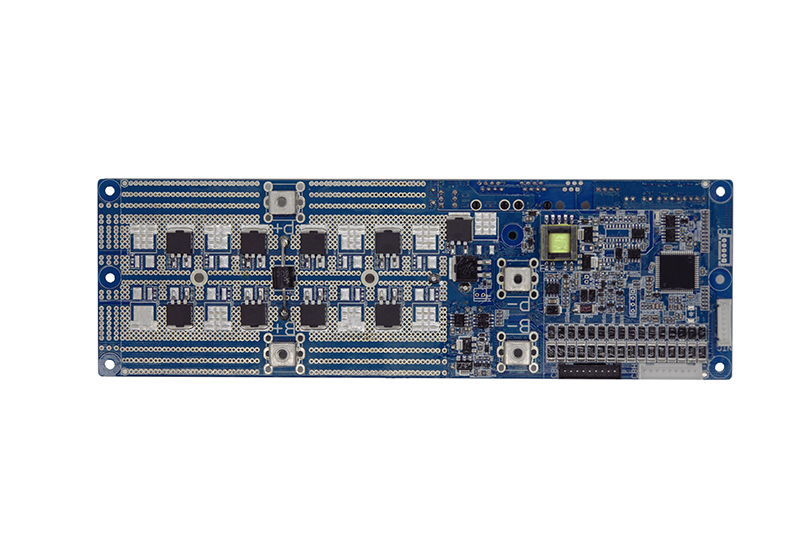

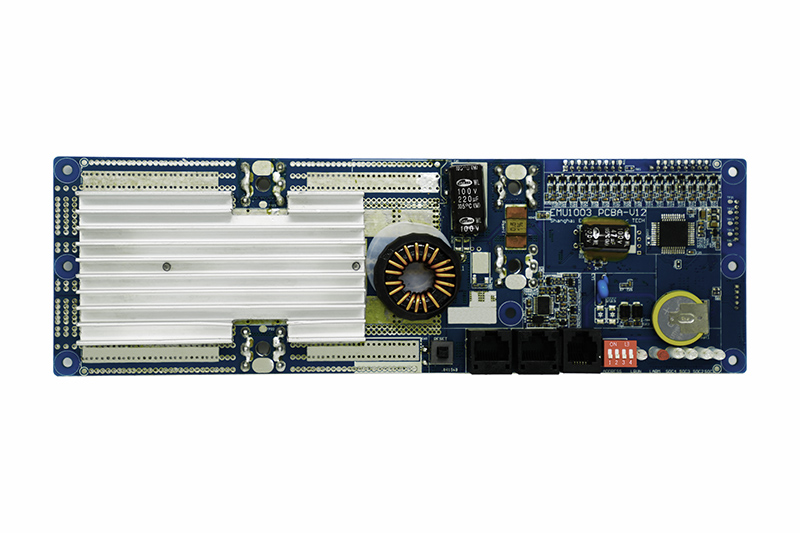

EMU1003-Telecom Lithium LFP Battery Pack BMS 50/75A

Product Introduction

(1) Cell and battery voltage detection:

Introducing our new and innovative product, Communication power backup application products, used in the working environment of base stations. The Cell Voltage Detection and Current Monitoring System. This advanced system is designed to provide accurate voltage detection and real-time monitoring of charge and discharge current for battery packs.

With a voltage detection accuracy of ±10mV at 0-45°C and ±30mV at -20-70°C, Current 50A/75A, passive current limiting, pre-charging and other functions are available, our system ensures precise and reliable measurements for battery charge and discharge current detection. This enhanced accuracy allows for effective and efficient monitoring of battery performance, ensuring optimal charging and discharging processes.

The hardware board supports internal communication, but cannot communicate with the inverter. The sampling check is 8PIN, and the temperature collection has a separate row socket.

One of the key features of our system is the ability to change the setting value of alarm and protection parameters through a host computer. This flexibility allows users to customize the system according to their specific requirements, ensuring the utmost protection and control over battery operations. By easily adjusting alarm and protection parameters, users can set thresholds for charge and discharge currents, avoiding any potential issues or damages.

To enable real-time monitoring of charge and discharge currents, our system utilizes a current detection resistor connected to the main circuit of the battery pack. This resistor collects and monitors the charge and discharge currents, providing accurate and up-to-date information. By continuously monitoring the current, the system is capable of detecting any abnormalities or deviations from the set parameters, thereby enabling timely alarms and protections.

Our Cell Voltage Detection and Current Monitoring System is engineered with reliability and user-friendliness in mind. It not only ensures accurate measurements and flexible control, but it is also easy to install and simple to operate. The user-friendly interface allows for seamless integration with a variety of battery packs and systems.

In conclusion, our Cell Voltage Detection and Current Monitoring System offers a comprehensive solution for accurate voltage detection and real-time monitoring of charge and discharge currents. With the ability to change alarm and protection parameters, and the capability to collect and monitor currents in real-time, our system provides a reliable and efficient approach for battery management. Upgrade your battery pack monitoring today with our innovative and advanced system.

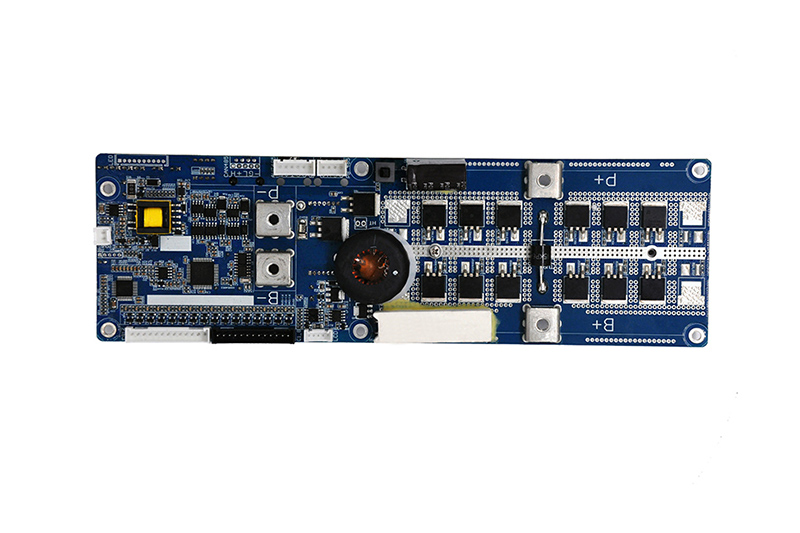

(2) Short circuit protection function:

It has the detection and protection function of output short circuit.

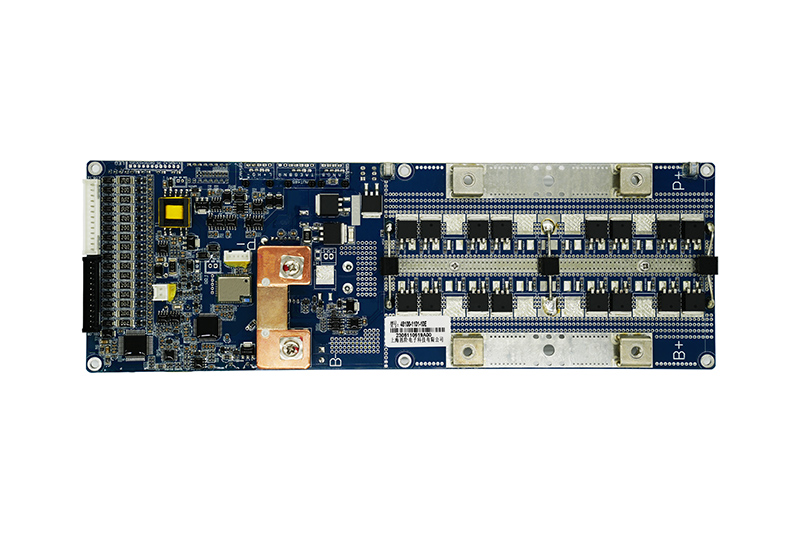

(3) Battery capacity and number of cycles:

Real-time calculation of remaining battery capacity, learning of total charge and discharge capacity at one time, SOC estimation accuracy better than ±5%. The setting value of the battery cycle capacity parameter can be changed through the upper computer.

(4) Equalization of intelligent single cells:

Unbalanced cells can be balanced during charging or standby, which can effectively improve the service time and cycle life of the battery. The balanced opening voltage and balanced differential pressure can be set by the upper computer.

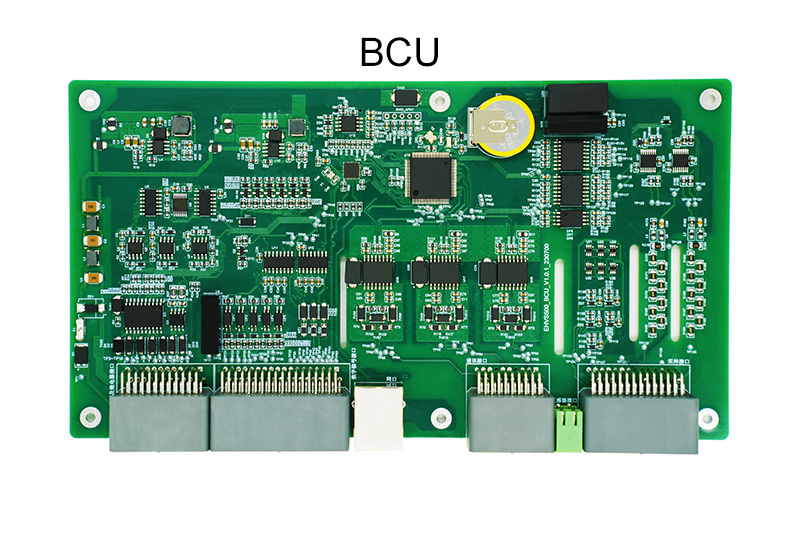

(5) One-button switch:

When the BMS is in parallel, the master can control the shutdown and startup of the slaves. The host must be dialed in parallel mode, and the dial address of the host cannot be turned on and off with one key. (The battery reflows to each other when running in parallel, and it cannot be turned off with one key).

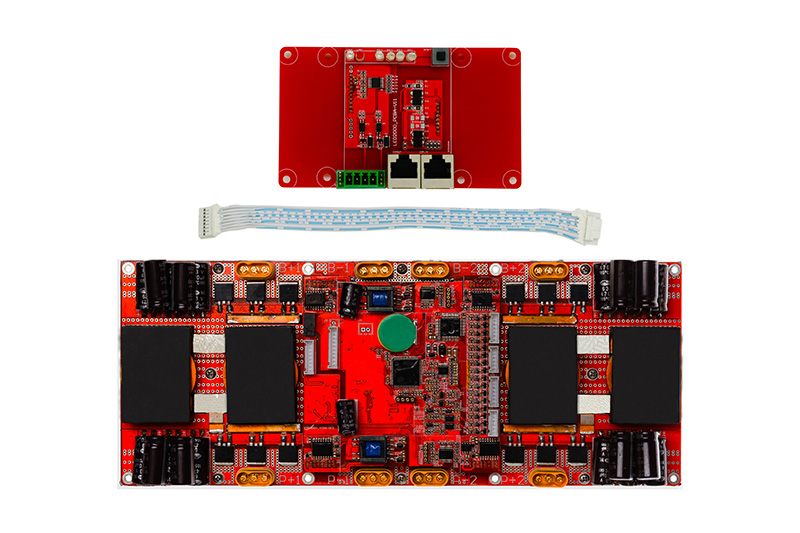

(6) CAN, RM485, RS485 communication interface:

CAN communication communicates according to the protocol of each inverter, and can be connected to the inverter for communication. Compatible with more than 40 brands.

(7) Charging current limiting function:

two modes of active current limiting and passive current limiting, you can choose one according to your needs.

1. Active current limiting: When the BMS is in the charging state, the BMS always turns on the MOS tube of the current limiting module, and actively limits the charging current to 10A.

2. Passive current limiting: In the charging state, if the charging current reaches the charging overcurrent alarm value, the BMS will turn on the 10A current limiting function, and re-check whether the charger current reaches the passive current limiting condition after 5 minutes of current limiting. (Open passive current limit value can be set).

2.(1) Cell and battery voltage detection:

The voltage detection accuracy of the cell is ±10mV at 0-45°C, and ±30mV at -20-70°C for battery charge and discharge current detection. The setting value of alarm and protection parameters can be changed through the host computer, and the current detection resistor connected to the main circuit of charge and discharge can be used to collect and monitor the charge and discharge current of the battery pack in real time, so as to realize the alarm and protection of charge current and discharge current, with excellent current accuracy at ±1.

(2) Short circuit protection function:

It has the detection and protection function of output short circuit.

(3) Battery capacity and number of cycles:

Real-time calculation of remaining battery capacity, learning of total charge and discharge capacity at one time, SOC estimation accuracy better than ±5%. The setting value of the battery cycle capacity parameter can be changed through the upper computer.

(4) Equalization of intelligent single cells:

Unbalanced cells can be balanced during charging or standby, which can effectively improve the service time and cycle life of the battery. The balanced opening voltage and balanced differential pressure can be set by the upper computer.

(5) One-button switch:

When the BMS is in parallel, the master can control the shutdown and startup of the slaves. The host must be dialed in parallel mode, and the dial address of the host cannot be turned on and off with one key. (The battery reflows to each other when running in parallel, and it cannot be turned off with one key).

(6) CAN, RM485, RS485 communication interface:

CAN communication communicates according to the protocol of each inverter, and can be connected to the inverter for communication. Compatible with more than 40 brands.

(7) Charging current limiting function:

Two modes of active current limiting and passive current limiting, you can choose one according to your needs.

1. Active current limiting:When the BMS is in the charging state, the BMS always turns on the MOS tube of the current limiting module, and actively limits the charging current to 10A.

2. Passive current limiting: In the charging state, if the charging current reaches the charging overcurrent alarm value, the BMS will turn on the 10A current limiting function, and re-check whether the charger current reaches the passive current limiting condition after 5 minutes of current limiting. (Open passive current limit value can be set).

What is the Use?

It has protection and recovery functions such as single overvoltage/undervoltage, total voltage undervoltage/overvoltage, charging/discharging overcurrent, high temperature, low temperature and short circuit. Realize accurate measurement of SOC during charge and discharge, and statistics of SOH health status. Realize voltage balance during charging. Data communication with the host through RS485 communication, parameter configuration and data monitoring through Upper computer interaction of the upper computer software.

Advantages

1. With a variety of external expansion accessories: Bluetooth, display, heating, air cooling.

2. Unique SOC calculation method: ampere-hour integral method + internal self-algorithm.

3. Automatic dialing function: parallel machine automatically assigns the address of each battery pack combination, which is more convenient for users to customize the combination.